MoMAS

MoMAS

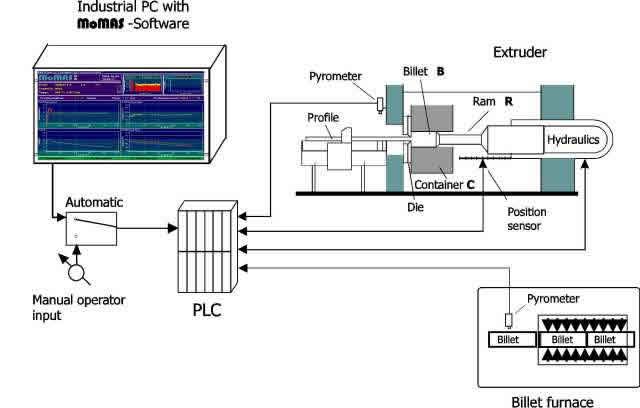

Choice of control input and modes of operation of MoMAS®

1. Ram velocity as control input

A billet temperature run is given as reference input to the furnace manually.

The billet temperature is measured before loading the billet into the container.

The optimal ram velocity is calculated using the measured billet temperature and

given as input to the velocity loop in PLC. The extrusion cycle is run by the PLC.

2. Ram velocity as control input with successive lowering of billet temperature

Extrusions are performed as above till the desired exit temperature is achieved.

The billet temperature is lowered by a pre-set value – say 5° C and the extrusions run.

The procedure is repeated till the allowed minimum billet temperature is reached.

3. Ram velocity and billet temperature as control input

A constant desired ram velocity is given by the operator. The billet temperature taper

run is calculated and given as reference input to the furnace temperature controls. The billet is heated and transported to the extruder.

The actual billet temperature is measured before introducing the billet into the container. The optimal ram velocity is calculated using the measured billet temperature and given as input to the velocity loop in PLC.